Glen Manufacturing Company Improvements

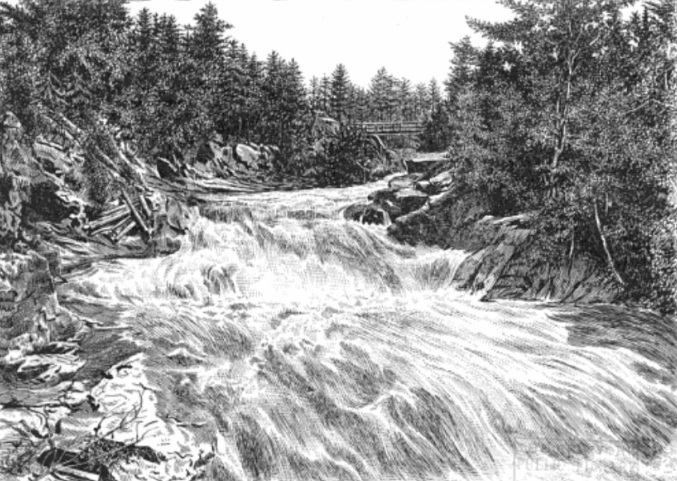

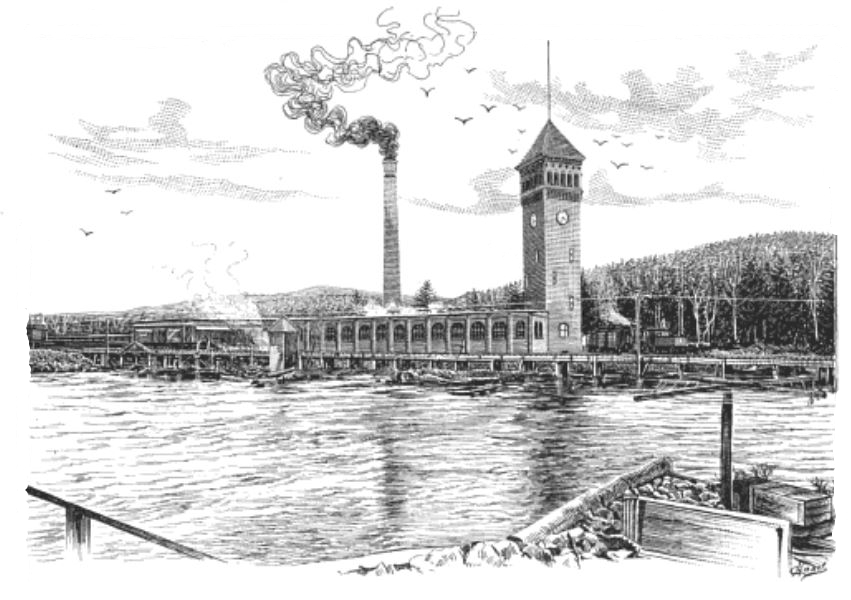

I wrote you some time ago regarding the vast improvements that the Glen Manufacturing Company were making at Berlin Falls, N. H., and which work was going on with great rapidity the day that I was there. Indeed, in going over the works of that great paper and pulp making establishment I made the estimate that there were about 500 men on the new works, blasting, excavating and building, and it looked to me as if they were going to tear up the whole town of Berlin. You see, Mr. Editor, the Glen Manufacturing Company has finished as far as the production of paper goes, for its mill is fully equipped with all the Fourdrinier machines they intend to put in for the time being, at least, but the part that the Glen has been playing is to fortify the enormous production of paper with the necessary water power first, and ground wood pulp second.

Now the Glen Manufacturing Company, up to the time when they made up their minds that they could well afford to increase their production of white paper, had all the necessary water power and ground wood pulp to insure their production of white paper without being compelled to go into the market for pulp. But when they made up their minds to increase the production of white paper, and did increase, they also made up their minds to do just what they are doing now, and that is to increase the water power and ground wood pulp mills in proportion.

The Glen Manufacturing Company, I can safely say, are expending over a half million dollars in building dams, race-ways, flumes and ground wood pulp mill, and when they have them completed, they will have all the necessary water power and ground wood pulp to supply their mills abundantly.In the first place, on the upper level, they have built a dam with a 22 foot head, and they are developing on the next level, 3,500 horse power of water. On the next levee where stands the No. 5 pulp mill, they are developing 3,500 horse power. On the next level they are developing under a 40 foot head, 5,500 horse power, and they are putting in four pairs of 45 inch Sampson-Leffel water wheels.

The No. 3 pulp mill that the Glen Manufacturing Company are also hoping to have it running by April first. The mill is a two story brick structure. Besides this, the Glen Company are adding new buildings, new machinery, new engines for No. 1, No. 4, and No. 6 mills that have also been improved and enlarged, They are also building a new warehouse 120 feet by 100. They are also increasing their production of sulphite pulp, and have this outfit already completed. They daily production of this sulphite mill will be 65 tons. They have increased the steam plant to nearly 1,200 horse power. They have added two batteries of new steam boilers, 21 in all of 150 horse power each. This improvement of course in the steam power of the mill is for cooking sulphite, drying paper, operating their machines and heating the entire plant.

As I said before, the Glen Manufacturing Company have now all their new Fourdriniers set up and running. In the No. 1 mill they have five machines: the William H. Taylor, Henry M. Knowles, I. B. Hosford John Mitchell and the Thomas McCormack. I suppose you wonder why I am using these names, but from the Glen Manufacturing Company's inception they have named the machines in honor of the officers of the company.

Now the Glen Manufacturing Company, up to the time when they made up their minds that they could well afford to increase their production of white paper, had all the necessary water power and ground wood pulp to insure their production of white paper without being compelled to go into the market for pulp. But when they made up their minds to increase the production of white paper, and did increase, they also made up their minds to do just what they are doing now, and that is to increase the water power and ground wood pulp mills in proportion.

The Glen Manufacturing Company, I can safely say, are expending over a half million dollars in building dams, race-ways, flumes and ground wood pulp mill, and when they have them completed, they will have all the necessary water power and ground wood pulp to supply their mills abundantly.In the first place, on the upper level, they have built a dam with a 22 foot head, and they are developing on the next level, 3,500 horse power of water. On the next levee where stands the No. 5 pulp mill, they are developing 3,500 horse power. On the next level they are developing under a 40 foot head, 5,500 horse power, and they are putting in four pairs of 45 inch Sampson-Leffel water wheels.

The No. 3 pulp mill that the Glen Manufacturing Company are also hoping to have it running by April first. The mill is a two story brick structure. Besides this, the Glen Company are adding new buildings, new machinery, new engines for No. 1, No. 4, and No. 6 mills that have also been improved and enlarged, They are also building a new warehouse 120 feet by 100. They are also increasing their production of sulphite pulp, and have this outfit already completed. They daily production of this sulphite mill will be 65 tons. They have increased the steam plant to nearly 1,200 horse power. They have added two batteries of new steam boilers, 21 in all of 150 horse power each. This improvement of course in the steam power of the mill is for cooking sulphite, drying paper, operating their machines and heating the entire plant.

As I said before, the Glen Manufacturing Company have now all their new Fourdriniers set up and running. In the No. 1 mill they have five machines: the William H. Taylor, Henry M. Knowles, I. B. Hosford John Mitchell and the Thomas McCormack. I suppose you wonder why I am using these names, but from the Glen Manufacturing Company's inception they have named the machines in honor of the officers of the company.

|

In No. 4 mill they have three more machines, one of which is the Dudley Porter, built by Rice, Barton and Fales; the names of the other two I don't recall. All the rest of the machines in this mill were built by the Pusey and Jones Company, of Wilmington, Del. The Thomas McCormack machine is a new one. and Mr. McCormack told me

when I was there that he made the best record on that machine from the very hour it was started up that he ever made on a machine in his life, and he has operated many. He claims that he started her up at a speed of 368 feet a minute, and ran her twelve hours without a break, and he says this is remarkable in starting up a brand new machine. The Glen Manufacturing Company have running at Berlin Falls, eight Fourdrinier machines, two 86-inch machines, one 102, on: 94, three 122, and one 90, making all told, 145 tons of white news paper. At Haverhill, Mass., they have three machines, one 88 inches and two 86 inches. One of these machines is a new one, also built by the Pusey and Jones Company,Wilmington, Del. In this mill they are making, or were making at the last report, forty tons of paper daily. So the Glen Manufacturing Company's total production of white paper, including Haverhill, is 185 tons daily. The Haverhill plant is a steam plant entirely, and all the raw material is shipped from Berlin. |

Article published by an unknown author in “The Paper Mill and Wood Pulp News” volume 20,

February 25, 1897.

February 25, 1897.